Turn Your Waste Into Revenue With Mobile Biochar Production

The Maine Kiln: America's Most Economical Mobile Biochar System — Towable, Simple, Profitable

✔ On-Site Waste Management

✔ Family Owned & Operated

✔ Turns Waste Into Resource

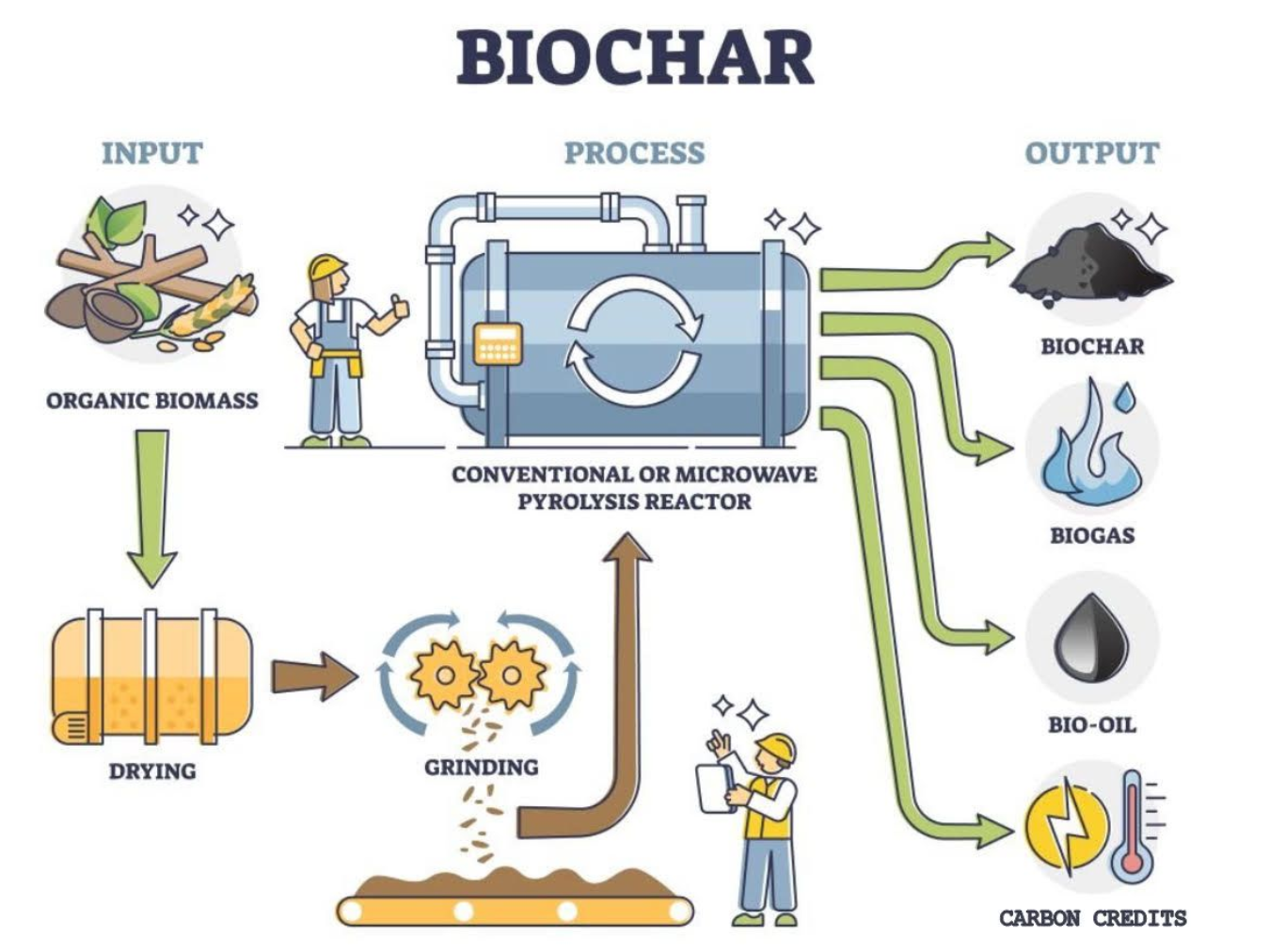

Biochar

is a carbon rich, charcoal like substance, produced by the thermal degradation of biomass in a low oxygen environment.

Made in USA

ROI Under 2 Years

Processes 1 Cubic Yard/Batch

Zero Fossil Fuels

Stop

Paying

to

Dispose

of

Organic

Waste

💸

High Disposal Costs

Generate revenue selling biochar instead of paying for waste disposal. Turn your cost center into a profit center.

📋

Regulatory Compliance

Enclosed firebox design with low emissions reduces permit requirements. Easier compliance than traditional burning methods.

⚙️

Complex Operations

Simple one-person operation with minimal training required. Roll biomass in, pull char out. No specialized expertise needed.

Our vision is to advance onsite

biochar production as the most sustainable and efficient solution for organic waste management

through advocacy and education.

Meet the

Maine Kiln

✔ Light enough to tow with 1/2-ton truck (competitor units need 1-ton)

✔ Custom-built trailer with 14-20 ft options for your needs

✔ Processes ~1 cubic yard per batch, produces 1/3 volume in biochar

✔ Enclosed firebox design reduces permit requirements

✔ Minimal smoke, low emissions for cleaner operation

✔ No fossil fuels required - powered entirely by wood waste

✔ Includes 8 barrels plus hooking tool

✔ Delivered road-ready to your location

✔ Built by family craftsmen in Westbrook, Maine since 1952

Explore Financing Options

Contact us to learn about ownership vs. leasing options and possible grant opportunities for biochar equipment.

Designed for Your Industry

On-Site Processing for Agricultural Waste, Wood Debris, Animal Bedding, Construction Materials and More...

🌾

Agriculture

Farms, vineyards, orchards, greenhouses processing crop waste, straw, nut shells

🌳

Landscaping & Arborists

Tree services, landscapers managing wood waste, branches, root balls

🏛️

Municipal Operations

Cities & towns handling storm clean up, park waste, urban forestry

Generate New Revenues

with Biochar Production

Real Results: Maine Kiln Success Stories

Discover how businesses are turning waste into profit

AGRICULTURE

From Waste Costs to Revenue Stream

A 300-acre apple and pear orchard in Washington reduced disposal costs by $15,000 annually while generating $22,000 in biochar sales to local organic farms. The Maine Kiln processes pruning waste, fallen fruit, and wooden bin materials year-round.

$37K

Annual Financial Impact

14 months

ROI Timeline

45 tons

Waste Processed Annually

15 tons

Biochar Produced

CANNABIS

Closing the Loop on Plant Waste

A 50,000 sq ft indoor cannabis facility processes stems, roots, and plant material into biochar for use in their growing medium. The closed-loop system reduced growing costs by 15% while achieving zero-waste certification.

15%

Growing Cost Reduction

12 months

ROI Timeline

30 tons

Waste Processed Annually

Zero Waste

Facility Certification

Explore Profitable Biochar Applications

Why Businesses Choose

Mobile Biochar Systems

💰

Economical

Most economical mobile biochar kiln in its class. ROI under 2 years with typical use.

🚚

Mobile

Lightweight, towable with standard 1/2-ton truck. No 1-ton trucks or heavy equipment haulers needed.

🌍

Sustainable

Carbon sequestration eligible for carbon credits. Decentralized, climate-positive impact.

Trusted by Operators Across North America

See what our customers say about the Maine Kiln and our service

★★★★★

"The Maine Kiln transformed our waste management completely. We went from paying $12,000 annually for disposal to generating $8,000 in biochar revenue. ROI in 18 months - couldn't be happier."

Sarah Mitchell

Operations Manager, Heritage Orchards

★★★★★

"We looked at four different biochar systems. The Maine Kiln was the only one we could tow with our existing fleet. The American craftsmanship shows - it's built like a tank and runs flawlessly."

James Kowalski

Facilities Director, Willow Creek Farms

★★★★★

"I was skeptical about the one-person operation claim, but it's absolutely true. My 62 year old father runs it solo without any issues. The enclosed design also made permitting surprisingly easy."

Marcus Chen

Owner, Chen Landscaping & Tree Services

PROUDLY MADE IN THE USA

American Craftsmanship & Innovation You Can Trust

Every Maine Kiln is fabricated in Westbrook, Maine by a family-operated business with high-end metalworking expertise since 1952. Built with locally sourced materials to exacting standards.

We are committed to continuously developing new designs, reactor vessels, renewable fuel sources and material handling techniques to enhance the performance and efficiency of our systems.

Meet Our Team

Decades of expertise paired with a steadfast commitment to sustainability

Kevin Bernard

Founder, CEO

Read Bio

Kevin is Experienced in sales and marketing, engineering, real estate, and sustainable technology. He began his professional career as an electronics engineer with a startup CD manufacturing company as part of a design team responsible for early innovations in compact disc manufacturing technology. He joined Dux Computers in 1992, a startup clone computer company. There, he gained hands-on experience building and repairing computers, as well as designing, installing, and troubleshooting office network systems, until the company ultimately ceased operations.

Transitioning into real estate, Kevin spent more than 20 years as a successful investment real estate broker, specializing in sales and marketing for investors and contractors. Building on this experience, Kevin founded a real estate development company focused on rehabilitating multi-unit residential properties, alongside a property management company to oversee renting of units. Over time, he assembled a portfolio of 16 apartment buildings, managing complex financing structures and coordinating multiple concurrent construction and redevelopment projects for each asset.

In 2019, Kevin founded Cannawaste recycling, which transitioned from cannabis waste to a manufacturer of biochar kilns.

Kris Bernard

Director of Sales

Read Bio

A startup veteran with 15+ years of executive leadership, specializing in scaling operations that blend efficiency with measurable impact. His career spans healthcare, higher education, and sustainability—industries where he has built systems that not only grow organizations but also improve lives. At Community Wellness, Kris led initiatives in remote patient monitoring to strengthen chronic care management and healthcare partnerships. Previously, at HotChalk and EAB, he drove client success and long-term growth across dozens of universities.

Today, Kris extends his expertise to sustainability as a board member at Mobile Biochar Systems, helping guide a company that is redefining organic waste management with mobile biochar technology. Passionate about innovation, scalability, and building enduring relationships, Kris is committed to solutions that deliver lasting change across industries.

Steve Peterson

Board Advisor

Read Bio

Peterson started his career as a CPA for the American Broadcasting Company (NY, LA and SF) for 11 years and then as CFO for publisher HarperCollins SF.

Peterson then immersed himself for 30 years in Silicon Valley working for numerous tech startups. He also co-founded three startups that were successfully sold. They included Sentrytrack, remote monitoring solution for municipalities, webKPI, winner of a QuickBooks "Awesome Add-On" Award and then WasteTrakr Technologies Inc. for cannabis waste. Steve then orchestrated the sale of WasteTrakr for its investors to the public company GCAC for shares.

In 2016, Peterson was hired at one of San Jose’s largest dispensaries as General Manager for Elemental Wellness and then ran two dispensaries in Oregon for investors. The Oregon properties were sold to Harborside in Oakland CA as part of a public reverse merger.

Peterson then worked with Tress Capital, an early investor in the technology for the cannabis industry. He led a newly formed group called Tress Solutions.

As a thought leader, he wrote two e-books on #salescomp and accounting services moving to the cloud.

Peterson currently heads up Business Development activities for the pubco GCAC “Global Compliance Applications Corp”, (CSE:APP). The company leverages the power of the blockchain to create new applications including Efixii track and trace, clearESG for brands to share sustainability efforts and the Efixii Uplift for NFT discount coupons. In 2024, GCAC acquired a streaming TV network, rebranded it as “CitizenGreenTV” and launched on Apple TV, Android, ROKU, Fire TV/AMZN and over the web. We have over 450 shows on the network, including artists such as Montel Williams. Steve is excited to connect his broadcasting career experience with the power of the blockchain in engaging a new generation of viewers and consumers.

Dr. Christopher Laine

Board Advisor

Read Bio

Dr. Laine is a world-class expert in regulated product development and human-machine interaction, evidenced across dozens of devices including implantable orthopedics, clinical life support, and surgical robotics platforms. A seasoned entrepreneur and tech executive, Dr. Laine guides MBS in developing a versatile and accessible biochar system, and leverages a biotech R&D background in support of biochar process and application development.

Download Our

FREE Biochar Guide

💲 Revenue Applications Guide

📐 Detailed Specifications

Prefer to Talk?

info@mobilebiochar.com

Phone

+1 (207) 233-6434

Location

Westbrook, Maine, USA

New Inquiry

Thank you for contacting us. We will get back to you as soon as possible. We have sent these 2 documents to your email:

Maine Kiln Spec. Sheet

Mobile Biochar Guide

Oops, there was an error sending your message. Please refresh the page and try again or contact us directly.

What types of feedstock can the Maine Kiln process?

The Maine Kiln processes wood waste, agricultural residues (corn stalks, straw, nut shells), animal bedding, cannabis/hemp waste, root balls, construction debris, paper products, cardboard, and more. Feedstock should be relatively dry for optimal processing.

Do I need special permits to operate?

The enclosed firebox design with minimal emissions significantly reduces permit requirements compared to open burning. Check with your local fire department, but many operators find permits easier to obtain than traditional waste burning methods.

How long does a batch take?

Processing time varies by feedstock moisture and density, but typical batches process in 3-6 hours. The system is designed for continuous operation with multiple barrels rotating through the process.

What's the typical ROI timeframe?

Most operators achieve ROI in under 2 years through a combination of eliminated disposal costs and biochar sales revenue. Exact timeframe depends on your waste volume and local biochar market prices.

What training is provided?

The Maine Kiln is delivered road-ready with comprehensive operating instructions. The system is designed to be intuitive - employees can be trained quickly. Additional support is available as needed.

What maintenance is required?

Minimal routine maintenance is required. Replacement parts and maintenance service plans are available. The rugged construction means years of reliable operation with basic care.

Can I qualify for carbon credits?

Yes! Biochar production sequesters carbon in stable form for hundreds of years, making it eligible for carbon credits. We can provide assistance with life cycle analysis and credit quantification.

What trailer size should I choose?

The 16-foot trailer (16 barrels) is our most popular configuration, offering excellent capacity while remaining highly maneuverable. Choose based on your waste volume and site accessibility needs.

Still have a question?

Frequently Asked Questions

For us, customer support means being more than a vendor – we’re your partner, connector and educator. We share knowledge openly and support your success to help strengthen the entire biochar industry.